Tradition meets Innovation: over 110 years of Optical Manufacturing Experience

Ever since the foundation in 1913 our staff have been perfecting our knowledge and technologies to bring you the best products in optics. Our manufacturing facilities in Bad Kreuznach, Germany, guarantee outstanding quality – Made in Germany. We continuously invest in our state-of-the-art machinery and in the education and training of our staff. Select your perfect filter from our large portfolio of optical filters.

If you need a customized solution, we are your partner from the kick-off to the Project completion. Our extensive experience and in-depth knowledge of a wide range of applications enables us to provide you with solutions that are perfectly tailored to your needs.

As a family owned company, we are passionate and committed to our customers and their success. You can expect long-term relationships based on trust and shared goals with us.

Custom Optical Filters for maximum Flexibility

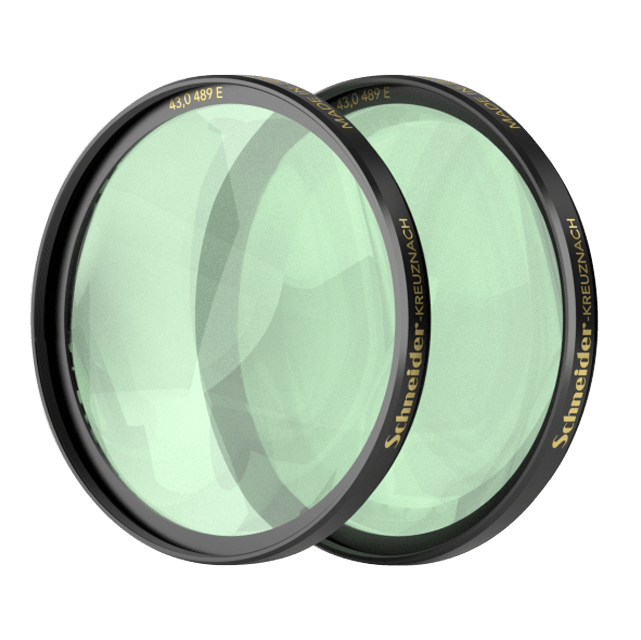

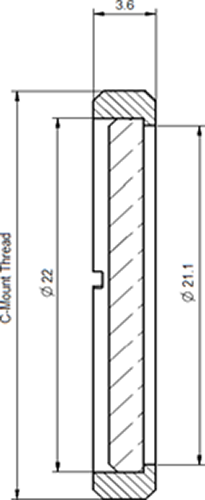

We design and manufacture both the mechanics and the coatings of our filters at Schneider-Kreuznach. This enables us to produce customized optical filters that meet your exact requirements and guarantee the highest quality standards.

Improve the performance and accuracy of your machines by using our optical filters. Reduce annoying reflections, minimize unwanted wavelengths, and increase the efficiency of your processes. Our filters are the key to the smooth and efficient operation of your industrial systems. They are durable and robust, ensuring long-term use.

Contact us to find the right solution for you.

Highest Quality and Reliability: our Filters put to the Test

Quality and reliability are top priorities at Schneider-Kreuznach. Our filters undergo rigorous quality control to ensure maximum reliability. We use only high quality glass from reputable manufacturers to achieve very low manufacturing tolerances. As a result, our filters are of consistently high quality. Their use allows you to accurately reproduce results, as the filters will perform nearly identically even after years of use.

Our industrial optical filters are rigorously tested to DIN and ISO standards to ensure they meet stringent environmental requirements. These tests evaluate their temperature stability and ability to withstand exposure to harsh chemicals and other environmental stressors. As a result, our filters excel in demanding industrial applications, providing consistent performance and reliability over time.

Precision down to the last detail: Our high vertical integration

We are proud of our technical expertise, which we consistently apply to the production of our lenses and optical filters through our high level of vertical integration at our Bad Kreuznach site. Each of the Schneider-Kreuznach products is manufactured with the utmost care and precision to provide you with the best possible performance and reliability.

Optics

We demand the highest standards of materials and manufacturing processes to ensure excellent image quality, starting with the production of the optics. Our standards go beyond the production of individual components. We master the entire production process from raw glass to finished filters and are able to process all common types of glass. Our special coating technologies give the optics or lenses the desired optical properties.

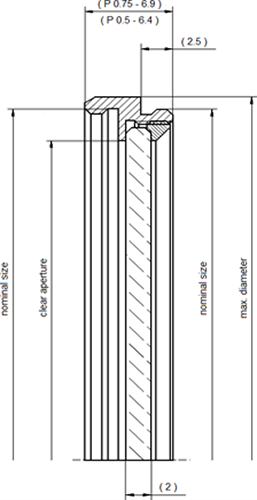

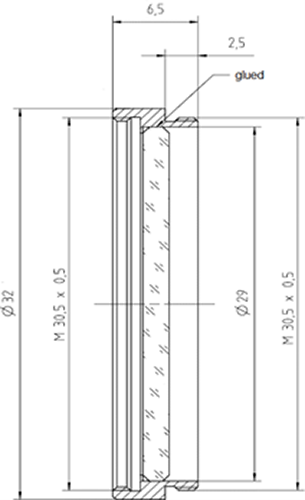

Mechanics

We do mechanical manufacturing in-house. We use the latest technologies and machinery to develop robust and durable filters. With our high-end 5-axis CNC milling machines, we have world-class machining capabilities that give us exceptional precision and flexibility. These powerful milling machines allow us to realize complex geometries and sophisticated contours in the mechanical components of our filters while maintaining high reproducibility. Electroplating is performed in-house under strict environmental conditions, allowing us to customize the surface coatings of our products to meet the specific requirements of our customers.

Assembly

Our lenses are assembled in dedicated clean rooms that provide a clean and controlled environment and ensure they are free of contaminants. Our qualified staff with many years of experience and expertise perform precise adjustments and calibrate the optics to the highest quality with the lowest tolerances.

Testing and Quality Assurance

Our test technology and quality assurance reflect our high quality standards. We use state-of-the-art technologies such as interferometers and 3D coordinate measurement technology to test the lenses we manufacture to ensure they meet the highest standards. Our ISO 9001 certified processes, metrology rooms and procedures ensure consistent and reliable production to meet our customers' high expectations.

Different needs, individual solutions: Let us advise you

Our sales and engineering professionals provide customers with a high level of expertise and responsiveness. We understand that the needs of our industrial customers can be diverse and complex. Whether it's technical specifications, the exact application environment, special customizations, or other unique requirements, we take the time to understand each customer's unique needs and provide customized solutions.

Our advice ranges from selecting the right filter to assisting with integration into existing systems. You can count on our experts to provide the best support and find the perfect solution. Our in-depth application knowledge and proven optical expertise enable us to provide customized solutions that combine mechanical robustness, reliability and the highest imaging accuracy.

This is the result of our decades of experience with extremely tight tolerances. We even go so far as to design and build our own manufacturing and metrology systems if there is no equipment available on the market that is accurate enough. Our customers value us not only for our technical expertise, but also for the dedicated and customer-focused advice we provide. We listen. We answer questions and make recommendations. It is important to us that our customers have all the information they need so that they can make the right decisions and achieve the best possible results.

Contact us. We will be happy to advise you.

All products at your glance - our digital product brochure (PDF)

Discover our wide range of high quality lenses, optical filters and accessories in our interactive eBrochure. Find the detailed compilation of all standard products currently available from Schneider-Kreuznach.

Our product brochure gives you a comprehensive overview of our entire product range, including all technical information. Whether you are looking for specific products or want to compare different options, our eBrochure has it all in one place.

Click on the link below to download our product brochure.

Download brochure (PDF)